British International School, Phuket (BISP) IB students Melanie Preen, Michael Larsson and Arsenii Barbashov, should be extremely proud of themselves, having recently made a significant impact on the life of a five-year-old girl living in Bangkok born with amniotic band syndrome causing the loss of her left arm.

British International School, Phuket (BISP) IB students Melanie Preen, Michael Larsson and Arsenii Barbashov, should be extremely proud of themselves, having recently made a significant impact on the life of a five-year-old girl living in Bangkok born with amniotic band syndrome causing the loss of her left arm.

Amniotic Band Syndrome, according to Michael Harrison MD, is a rare condition caused by strands of the amniotic sac that separate and entangle digits, limbs, or other parts of the fetus. This constriction can cause a variety of problems depending on where strands are located and how tightly they are wrapped, and in her case, these bands were wrapped around her left arm, causing a significant reduction in the flow of blood, ultimately resulting in a loss of her limb just below the elbow

“Joren, the little girl’s father, contacted me after reading an article in The Phuket News about our students having the capability to 3D Print prosthetics,” said Jonathan Clark, head of ICT & computing at BISP.

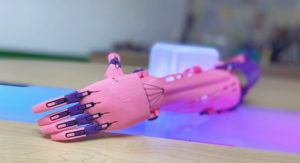

“The team then took charge of the project, working with scale photographs of the girl’s arms to accurately produce a suitable fit, and after much hard work and perseverance to perfect the 3D designs, the students were successful in printing and assembling the arm to the required specifications,” he added.

“The BISP team CAS project, involved the creation of a fully functional prosthetic arm, utilizing to the fullest extent, the technological opportunities at BISP.”

Inspired by the project and his students, Jonathan added, “It has been overwhelmingly satisfying for the students to see images of the girl wearing their 3D Printed creation. Although the family did not wish for the images to be made public, they are extremely grateful to Melanie, Michael, and Arsenii, and are thrilled to see their little girl getting used to her new arm.”

Inspired by the project and his students, Jonathan added, “It has been overwhelmingly satisfying for the students to see images of the girl wearing their 3D Printed creation. Although the family did not wish for the images to be made public, they are extremely grateful to Melanie, Michael, and Arsenii, and are thrilled to see their little girl getting used to her new arm.”

The Phuket News spoke with the students about their involvement in the project and how it has made an impact on their own lives and future goals. With quite a touching altruistic mindset, they shared their thoughts. Michael Larsson stated, “I was extremely happy to be part of this project which could help someone. Around the world, there are people who are put in unfortunate situations, and for several reasons may not be able to help themselves, whether it be financial, social or other factors. So I think it is important that those who do have the resources should help out those who don’t. Considering my interests and hobbies, I saw this project as more of an opportunity rather than an activity. I had the opportunity to both learn from this new experience with 3D printing and some of the 3D designs and also had this opportunity to help someone who needed it.

Although we only helped one person, I think it shows that if we really put the time and effort, we could help people all over the world who need it. This project also showed the true capabilities of technology and how this will hopefully be utilized in the future to help more in need, despite some of the disadvantages or concerns.”

Student Arsenii Barbashov stated, “Throughout the project, I had a positive and inspiring experience. Although our group helped only one person, it is still a great achievement for us and our school community as it is well known that the hardest part of every great project is doing the first steps. The perfect reward for completing this project was knowing that you helped to improve someone’s life. Moreover, when you are making a prosthetic arm, you are putting a part of your soul into it, which makes every prosthetic unique. Now reflecting on our project, I think that we, and society as a whole, should be aiming to provide bigger opportunities for everyone and that everyone must be given a chance for success.”

Melanie Preen wrote to The Phuket News to say, “I am glad to have joined this project as I know that I’ve made an impact on someone’s individual life. My motivation for the project was to enhance the plethora of skills needed in today’s society being: problem-solving, decision making, benevolence and applying technology to alleviate problems. For instance, through available resources online, we were able to learn how to craft the prosthetic hand by combining 3D printing and build these printed components tangibly.

Melanie Preen wrote to The Phuket News to say, “I am glad to have joined this project as I know that I’ve made an impact on someone’s individual life. My motivation for the project was to enhance the plethora of skills needed in today’s society being: problem-solving, decision making, benevolence and applying technology to alleviate problems. For instance, through available resources online, we were able to learn how to craft the prosthetic hand by combining 3D printing and build these printed components tangibly.

Throughout the process, we were able to enhance these aforementioned skills through collaborative efforts and heuristically understanding the capabilities of technology in our digital age to impacting the day-to-day life of a little girl.

Overall, this project allowed me to propel my aspirations to be a female role-model for the STEM community and emanate impactful attitudes towards our school community. I hope that me and my teammates will continuously emulate our success in the future – by utilizing technology to deliver solutions that are much needed in our world full of environmental and social issues.”

After following up with Mr Joren a few months after his daughter received her new prosthetic, he stated she is doing quite well. “She had been asking for a few months after initially contacting BISP, “Daddy when am I getting my new hand,” so now that she has it she is quite excited. Of course, there are some adjustments that need to be made as life with the articulating prosthetic is new for her. As with wearing a new pair of shoes, there is the time needed to break them in and similarly, she is working on getting used to the weight and mechanics of the prosthetic. She was very happy to assist in the design of her prosthetic, choosing pink for the primary colour, and purples for the highlights and articulating components.” Mr Joren added that while at times it may be a challenge for his daughter to get used to the new limb, Mr Clark and the CAS student group at BISP IP are continuously working with her to improve the ease and comfort of the articulation, expressing that her 3D printed prosthetic is a vast improvement over her first prosthetic, which was primarily aesthetic in nature when she was two years old.

Jonathan Clark said of the project, “The work undertaken has fully encompassed what CAS is all about and stands for, that is Creativity, Action and Service.”

According to the amputee coalition, 3D printing is a relatively new but promising technology available to amateurs as well as professionals. Free, editable designs are available online without copyright. Anyone with access to a 3D printer, such as the students at BISP IB program, and creative mentality, can create a prosthesis at quite a reasonable expense. A prosthetic hand can cost hundreds of thousands of baht; however, a 3D-printed prosthesis could be made for as little as B1,500.

3D-printing materials cannot yet replace the long-term durability of traditionally-made prostheses. However, this will soon change. In the meantime, technology is making cost-effective prosthetics a reality and encouraging creative people from all over the world to participate in their design.

Right now, suggests the amputee coalition, the field of 3D-printed prosthetics is in its infancy, and many models are still in the developmental stage. The 3D movement inspired many to take matters into their own hands in a “do it yourself” spirit, providing the tools for many to make homemade prosthetics. This practice is now influencing the professional market in how professional-grade prosthetics are made.

We can expect to see, suggest the amputee coalition, more companies prototyping various prosthetics using 3D-printing technology. 3D printing using higher-end metals such as titanium and other alloys is not common practice now, however, they are expected to be more so in the future.

For more information on Amniotic Band Syndrome click here

This story was first published on The Phuket News in print and online (Sunday February 9th 2020).